3D printing with silicone is an appealing prospect, especially given the long list of material characteristics. Notably, silicone has high heat resistance, tolerating temperatures above 200°C (392°F), its inert nature and biocompatibility make it widespread in medical applications, and sealing and electrical insulation properties lend the material to various uses in many sectors.

Perhaps, then, it is surprising that the use of silicone by the additive manufacturing industry is not more widespread.

I spoke to Thomas Batigne, Co-founder and President of Lynxter, to learn how his company is unlocking the opportunities for this versatile material and solving the technical challenges required to make silicone 3D printable.

Lynxter began when Airbus spotted a 3D printing system developed by the co-founders at an entrepreneurship contest. Bolstered by interest from the aerospace company, Batigne, and the team developed a modular, delta-style 3D printer that also caught the eye of Total and Schneider Electric. Many customers were particularly interested in Lynxter’s silicone 3D printing capabilities, so the development path to the Lynxter S300X began.

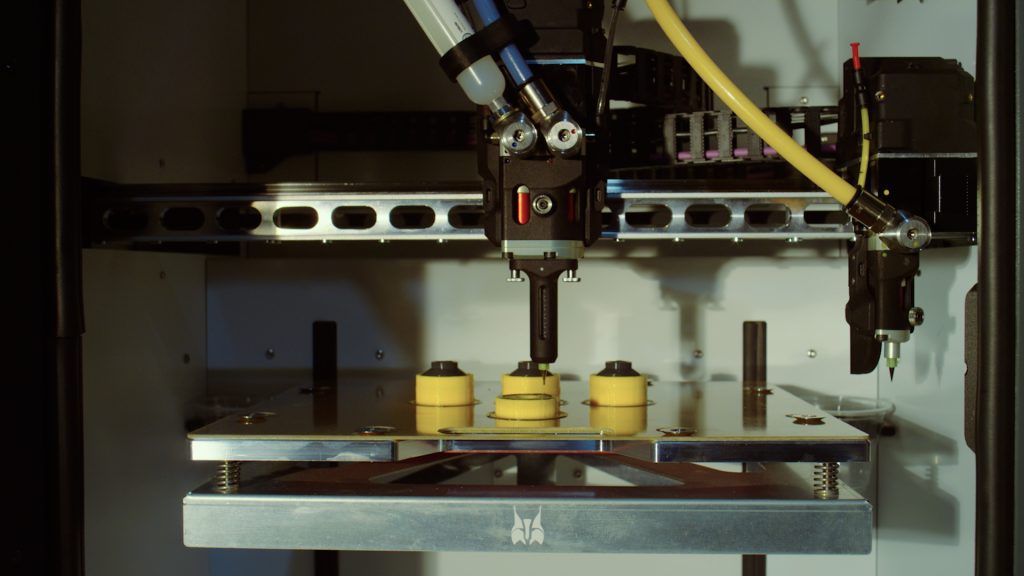

The Lynxter S300X 3D printer is designed for silicone and polyurethane materials. It can 3D print at different points on the shore hardness scale with liquid silicone elastomers and polyurethanes.

Batigne elaborated on growth from delta to IDEX systems. The expansion was inspired by the goal of improving calibration and maintenance and reducing cost. “It’s like buying an SLR camera but only using one lens. It doesn’t make any sense, but that’s what some people were doing,” Batigne explained, comparing the redundant modularity for users who wanted access primarily to silicone. The goal was to create a machine “as free to design and print whatever you want, as you would be with a thermoplastic 3D printer.”

How to 3D print silicone?

Batigne elaborated on the technology side, emphasizing how silicone printing differentiates from thermoplastics. In regular 3D printing, one nozzle can manage both the primary material and support, leveraging layer fusion variances for easy removal. But silicone printing’s strength – its inherent cohesion – becomes a challenge with support structures, which are tougher to separate due to their adhesion.

To address this, Lynxter innovated a gel support that synergizes with silicone.

The S300X has two tool heads, the LIQ21 and the LIQ11. The former handles the 3D printing of the component, while the latter produces the water-soluble supports required.

When asked about how the rheological properties of silicone influence the structures being made, Batigne offered, “The more gel-like is the silicone, the easier it will be to 3D print because it will just stay there.” However, the trickiness lies in layering. Getting the right viscosity is essential, as it affects not only the printability but also the material’s resistance to UV and elasticity. Highlighting Lynxter’s advantage in the market, Batigne remarked, “Because we use PCP pumps, we can dose and move these super viscous materials that are just impossible to pour in a vat or jet.”

The LIQ21 dispenses a single-part liquid hydrogel, which is water-soluble and environmentally friendly. This head is paramount for overhangs.

By focusing on chemistry, Lynxter has maintained the integrity and properties of the materials, making them identical to those used in medical or industrial fields. Lynxter’s materials are not mere imitations. When some companies provide ‘ABS-like’ or ‘PA-6-like’ materials, Lynxter ensures that their products come from fields where people are familiar with them, obviating the need for fresh certifications.

As Batigne revealed, the healthcare industry is a primary focus for Lynxter, addressing the shortcomings of current 3D printers in the market. He highlighted the issues with photo-activated resins regarding elasticity, durability, and UV aging. Silicone 3D printing is a solution to these challenges, particularly in creating medical devices.

Achieving high resolution is crucial. Yet, the limitation of the material extrusion process lies in the nozzle’s diameter and the layer’s height. Batigne clarifies, “We have the same kind of resolution for an industrial FDM printer, which is usually more than enough for what we have to do.”

With innovation, challenges abound. Batigne discussed the challenges of silicone printing, especially when dealing with fine structures. To overcome these, Lynxter uses intelligent XY supports, maximizing print fidelity even in intricate designs.

A strength of Lynxter’s process is its minimal post-processing requirements. He shows me a 3D printed piece of silicone, “There was no pretreatment. I just wait for the silicone to cure at room temperature,” shared Batigne. On the topic of curing or the process of setting a material, Batigne says that for most materials, the process can be entirely executed within the machine. In other cases, a simple external heat treatment might suffice. They can also apply a treatment called “soft touch,” a silicone varnish making the end product smoother.

Unlocking additive applications

Another application demonstrated by Batigne shows how silicone caps can improve the process chain for surface treatments. Today, in the aeronautical sector, masking – or shielding a part of an object from treatment – is painstakingly executed using adhesive tape. This procedure, though essential, is labor intensive. But Batigne believes there’s a better way – using 3D printed silicone caps for masking. Caps can be produced to the specific geometry required, and fitting them is as simple as putting the lid on a bottle.

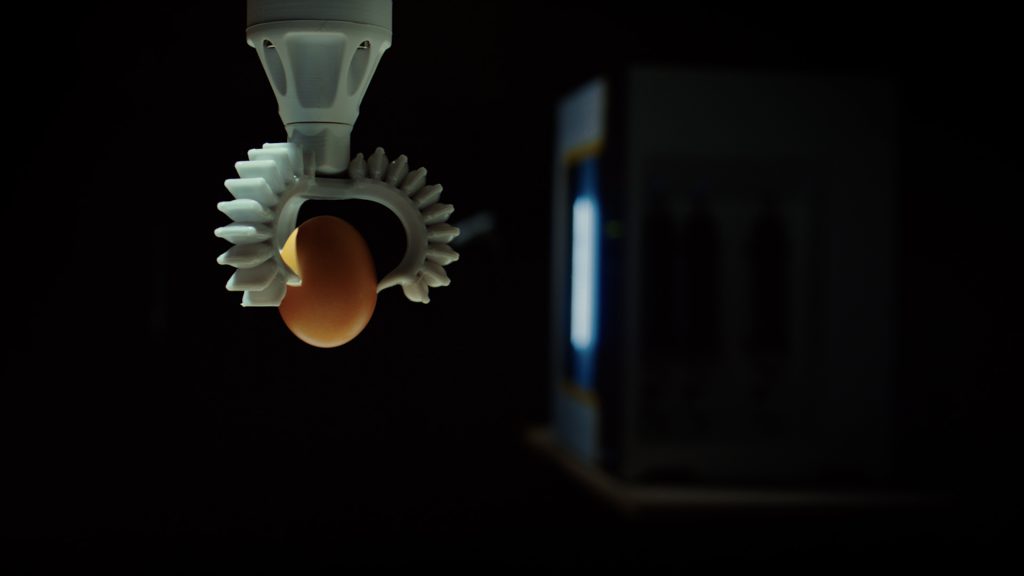

Another exciting development in this sector is the advent of multi-material silicone 3D printing. Batigne shared insights about blending technologies: “Now that these technologies are maturing, we can start mixing them.” Lynxter’s experiments have involved combining silicone with conductive ink, thermoplastics, and hydrogels. This mix promises to herald soft robots – those grippers that flex and grip, almost mimicking a human touch.

Silicone, given its biocompatibility, is carving out a significant niche in the medical sector. Batigne mentioned several applications: “We’ve been able to print tailor-made masks for burn victims, cooling devices for cancer treatments, and even boluses to slow down lasers targeting specific depths in skin cancer treatments.”

A particularly striking advancement is in the area of prosthetics: “When done with skin cancer, you might need to cut your nose. You can replace that with a super accurate model of your nose made out of silicone.”

A new market opportunity

Unlocking these materials will create a sizeable market for applications. With thermoplastics leading the global market in additive manufacturing, where does silicone stand? By Batigne’s estimates, if global silicone figures are around $20 billion compared to plastics at $31 billion, the market potential for silicone in 3D printing is substantial.

Lynxter’s leadership in the silicone 3D printing industry is undeniable, holding a substantial market share. “No one has taken this market yet. We’re the biggest in this field,” highlighted Batigne, indicating the expansive 400 million market opportunity. But for Lynxter, the numbers are just the beginning.

As the discussion winds down, Batigne touches upon Lynxter’s unique position in the market. Silicone 3D printing is still a nascent field, but Lynxter’s early foray into it, coupled with its unmatched offerings at competitive prices, sets it apart. Batigne confidently asserts, “It’s a game-changer. Now, it’s become usable at the correct price, and it’s ready to print.”

Batigne unveiled their upcoming project with Synthene, one of the largest polyurethane manufacturers in France. “It’s a true automotive-grade PU,” he explained, hinting at new product releases and significant software upgrades on the horizon. These advancements, Batigne believes, will further position Lynxter at the forefront of 3D printing with these versatile materials.

Read more about silicone 3D printing and Lynxter here.

Featured image shows Lynxter silicone 3D printing. Photo via Lynxter.